Here, you can see the film adhering to the backing. Note that the laminating layer won't stick to the backing since the film has taken its place.

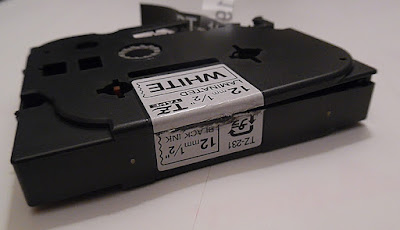

There's 3 parts to a TZ cartridge,

#1: the backing which is essentially double back tape,

#2: the thermal film which prints on the back of the laminating layer

#3: a clear laminating layer which protects the label.

So it's time to get out the butter knife.

Break the label so the top will come off.

Here's the back of the top cover, you'll note that I've broken one of the locking tabs.

The open cartridge:

The spindle with the broken film. I've actually cut the film to take out the spindle and to make a clean join.

The spindle has a little metal finger protruding from it which fits neatly into a slot. If you look from the bottom of the cartridge, you can see the little metal piece. This finger is what keeps the film spindle tight so it doesn't develop slack.

The spindle turns counter clockwise as can be seen by this marking on the top cover.

Just take some scotch magic mending tape and cut a couple of strips. You may need to trim those strips with a pair of scissors to fit the width of the film. It's ok if the pieces don't exactly fit the film as long as it's narrower than the film. Take those strips and connect the broken pieces of tape together. You can tape it on both sides to make sure it's got a good hold. If the film has come off of the spindle, just tape it to the spindle and wind it a bit.

Put the film spindle back in and thread it properly and take out the slack. Slack in the film is very bad. Very very bad.

And put the top cover back on and get the backing and the lamination layer threaded and adhering properly.

You can see why there's always a bit of wastage with P-touch tapes because of the distance between the printhead and the final output of the cartridge, about an inch. That wastage has to occur to keep the laminating layer stuck to the backing and keep it all aligned and exiting through the final slot.

No comments:

Post a Comment